Supply ODM/OEM

Relying on the company's platform and innovative advantages in the superhard material industry, the company has been deeply involved in the superhard material industry, adhering to the business philosophy of "quality as the foundation, integrity and development", and specialization and large-scale production of the superhard material industry and products.

We support customization, you can contact us if you have any size, material and shape requirements.

9:00 am to 9:00 pm China time

Get professional feedback within 2-7 working hours. Quick orders are shipped in 2-3 working days, depending on stock availability.

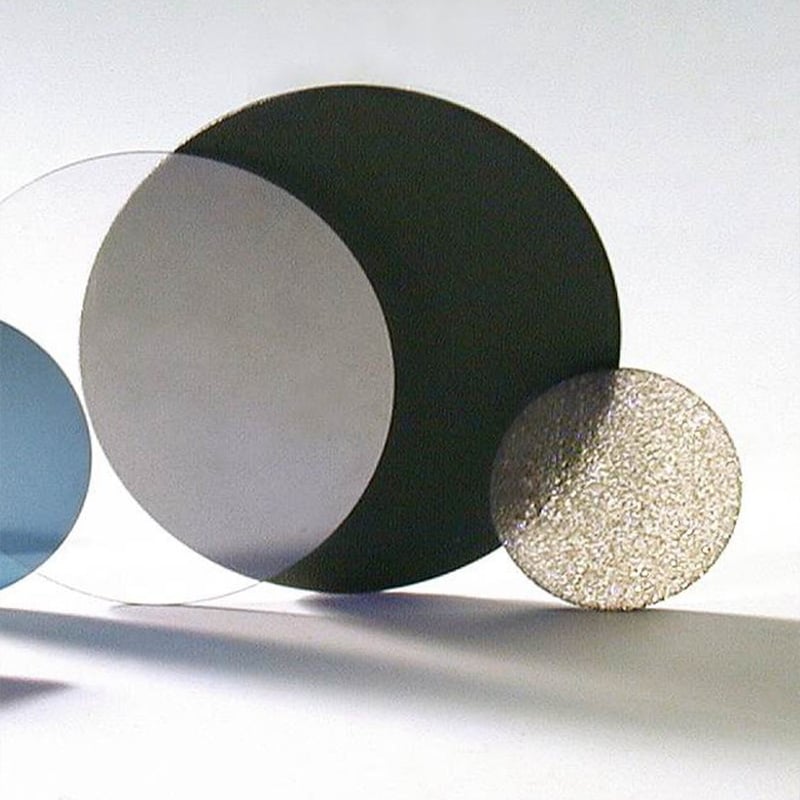

polycrystalline CVD (chemical vapour deposition) synthetic diamond products are manufactured by a chemical vapour deposition (CVD) process and are subject to tightly controlled growth conditions during manufacturing and equally stringent quality control procedures.

Specifications

1.High wear resistance to chipping and fracture

2.Excellent thermal stability

3.Excellent toughness sharpness

4.Various size

Tolerance of Thickness: ±25um

Flatness: <4um/cm

Thermal conductivity three types : 1300W/mK; 1500W/mK;1800 W/mK (more than 9 times compard to Silicone 139 W/mK)

Density: 3.5g/cm3

Young's modulus: 1000-1100Gpa

Growth side surface finish: <100 nm Ra

Nucleation side surface finish: <30 nm Ra

One of many remarkable properties of diamond is its unsurpassed thermal conductivity. It exceeds that of copper by a factor of five. In contrast to metals, where heat is conducted by electrons, lattice vibrations are responsible for the high thermal conductivity of diamond.

Thermal conductivity can be tailored within the range of 1000-1800 W/mK to enable matching cost/performance to the needs of the application.

Nowadays CVD diamond made by our Laboratory is used as mounts for high-power integrated circuits and laser diodes.

Standard Sizes

Size: Up to diameter 65 mm, larger sizes on request

Surface: Both sides polished

Raw thickness: Between 0.3 mm and 1.5 mm

Polished thickness: Between 0.2 mm and 1.0 mm